DIN7991 Hex Socket Countersunk Screw Giredhi Carbon Steel Zinc Yakaputirwa Giredhi 8.8 10.9

DIN7991 Hex Socket Countersunk Screw Giredhi Carbon Steel Zinc Yakaputirwa Giredhi 8.8 10.9

Tsanangudzo

KUKURUMIDZAMhinduro

KUKURUMIDZAquote

KUKURUMIDZADelivery

AKAGADZIRIRA KUENDERERA KUNHU

10000+ SKU mudura

Isu tinozvipira kune RTS zvinhu:

70% zvinhu zvinotumirwa mukati memazuva mashanu

80% zvinhu zvinotumirwa mukati memazuva manomwe

90% zvinhu zvinotumirwamukati memazuva gumi

Mahodha akawanda, ndapota taura nevatengi

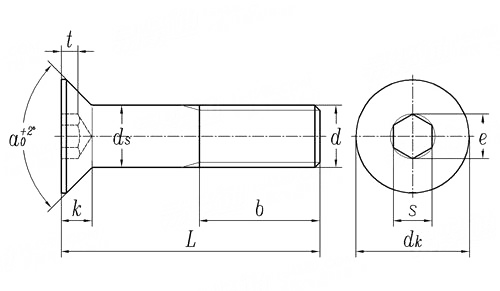

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Pitch | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | mari.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L>200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Max=Nezita | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Max=Nezita | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Nominal | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Max=Nezita | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Tsanangudzo yedetail

High simba fasteners anoburitsa crispness kana galvanized. Unoda kunyatsotarisirwa.

Hydrogen embrittlement inowanzoonekwa nekunonoka kuputsika pasi pekunetseka. Pave paine zvitubu zvemotokari, washers, screws, mashizha zvitubu uye zvimwe zvikamu zvakabatiswa, mumaawa mashoma mushure memusangano waputswa, chikamu chekutyoka che40% ~ 50%. Mukuita kushandisa macadmium-plated zvikamu zvechigadzirwa chakakosha, pakanga paine batch crack fracture, uye dambudziko rekiyi renyika rakagadziriswa uye maitiro ekuita dehydrogenation akagadzirwa. Uyezve, pane zvimwe hydrogen embrittlement haaratidzi kunonoka kutsemuka chiitiko, akadai: electroplating hanger (simbi waya, mhangura waya) nokuda nguva dzakawanda electroplating uye pickling plating, hydrogen kupinda kwakanyanyisa, kazhinji kuonekwa mukushandiswa peta chichaitika brittle kutsemuka chiitiko; Mandrel yepfuti, mushure menguva dzinoverengeka dzechroming, yakawira pasi ndokutyoka; Zvimwe zvikamu zvakadzimwa (zvakakura zvemukati kushushikana) zvichatsemuka kana pickling. Zvikamu izvi zvakanyanya hydrogenated uye zvinotsemuka pasina kushushikana kwekunze, izvo zvisingakwanisi kushandiswa kudzorera kuoma kwepakutanga ne dehydrogenation.

Iyo yakakwirira simba rezvinhu, iyo yakakura iyo hydrogen embrittlement kunzwa. Iyi ipfungwa yakakosha inofanirwa kujekeswa nehunyanzvi hwekurapa kwepamusoro pakugadzira magadzirirwo emagetsi emagetsi. Simbi dzine simba rekusimba σb> 105kg/mm2 dzinodiwa nemitemo yenyika dzinofanirwa kuve pasi pekunetseka kwekutanga-kupisa uye kurapwa kwepashure kwedehydrogenation zvinoenderana. Indasitiri yekuFrance yendege inoda inoenderana dehydrogenation kurapwa kwezvikamu zvesimbi zvine simba regoho σs> 90kg/mm2.

Nekuda kwekunyorerana kwakanaka pakati pesimba resimbi uye kuoma, zviri nyore uye zviri nyore kutonga hydrogen embrittlement senitivity yezvinhu nekuoma kupfuura nesimba. Nekuti yakaringana chigadzirwa kudhirowa uye machining maitiro anofanirwa kucherechedzwa nekuoma kwesimbi. Mune electroplating, takaona kuti kuoma kwesimbi kwakatenderedza HRC38 kwakatanga kuratidza njodzi yekutyoka kwehydrogen embrittlement. Kune zvikamu zvakakwirira kupfuura HRC43, dehydrogenation inofanirwa kutariswa mushure mekuputirwa. Kana kuoma kuri kuita HRC60, kurapwa kwe dehydrogenation kunofanirwa kuitwa nekukurumidza mushure mekurapwa kwepamusoro, zvikasadaro zvikamu zvesimbi zvinotsemuka mukati memaawa mashoma.

Packing

Nezvedu

* Iyo inotevera dhizaini inoratidza akasiyana kutengeserana incoterms. Ndapota sarudza yaunoda.

HOT-SALE PRODUCT

Hunhu Kutanga, Kuchengetedzwa Kwakavimbiswa