DIN912 T2 Mhangura Hex Socket Cup Musoro Chikurukuru

DIN912 T2 Mhangura Hex Socket Cup Musoro Chikurukuru

Tsanangudzo

KUKURUMIDZAMhinduro

KUKURUMIDZAquote

KUKURUMIDZADelivery

AKAGADZIRIRA KUENDERERA KUNHU

10000+ SKU mudura

Isu tinozvipira kune RTS zvinhu:

70% zvinhu zvinotumirwa mukati memazuva mashanu

80% zvinhu zvinotumirwa mukati memazuva manomwe

90% zvinhu zvinotumirwamukati memazuva gumi

Mahodha akawanda, ndapota taura nevatengi

| d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | |

| P | Shinda yakakora | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 |

| Fine thread | / | / | / | / | / | / | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 2 | 2 | |

| Very Fine thread | / | / | / | / | / | / | / | / | / | 1 | 1.25 | / | / | 1.5 | 1.5 | |

| b | Reference value | 14 | 15 | 16 | 17 | 18 | 20 | 22 | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 |

| dk | Max (Smooth) | 2.6 | 3 | 3.8 | 4.5 | 5.5 | 7 | 8.5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 |

| Max (Knurl*) | 2.74 | 3.14 | 3.98 | 4.68 | 5.68 | 7.22 | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 27.33 | 30.33 | |

| Min | 2.46 | 2.86 | 3.62 | 4.32 | 5.32 | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | |

| ds | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | |

| k | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.7 | 7.64 | 9.64 | 11.57 | 13.57 | 15.57 | 17.57 | 19.48 | |

| s | Nominal | 1.3 | 1.5 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 14 | 17 |

| Min | 1.32 | 1.52 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | 17.05 | |

| Max | 1.36 | 1.56 | 1.56 | 2.06 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | 17.23 | |

| t | Min | 0.6 | 0.7 | 1 | 1.1 | 1.3 | 2 | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Hurefu hweshinda=b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| d | (M22) | M24 | (M27) | M30 | (M33) | M36 | M42 | M48 | M56 | M64 | M72 | M80 | M90 | M100 | |

| P | Shinda yakakora | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6 | 6 | 6 | 6 |

| Fine thread | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Very Fine thread | 1.5 | / | / | / | / | / | / | / | / | / | / | / | / | / | |

| b | Reference value | 56 | 60 | 66 | 72 | 78 | 84 | 96 | 108 | 124 | 140 | 156 | 172 | 192 | 212 |

| dk | Max (Smooth) | 33 | 36 | 40 | 45 | 50 | 54 | 63 | 72 | 84 | 96 | 108 | 120 | 135 | 150 |

| Max (Knurl*) | 33.39 | 36.39 | 40.39 | 45.39 | 50.39 | 54.46 | 63.46 | 72.46 | 84.54 | 96.54 | 108.54 | 120.54 | 135.63 | 150.63 | |

| Min | 32.61 | 35.61 | 39.61 | 44.61 | 49.61 | 53.54 | 62.54 | 71.54 | 83.46 | 95.46 | 107.46 | 119.46 | 134.37 | 149.37 | |

| ds | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Min | 21.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 41.61 | 47.61 | 55.54 | 63.54 | 71.54 | 79.54 | 89.46 | 99.46 | |

| k | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Min | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 41.38 | 47.38 | 56.26 | 63.26 | 71.26 | 79.26 | 89.13 | 99.13 | |

| s | Nominal | 17 | 19 | 19 | 22 | 24 | 27 | 32 | 36 | 41 | 46 | 55 | 65 | 75 | 85 |

| Min | 17.05 | 19.065 | 19.065 | 22.065 | 24.065 | 27.065 | 32.08 | 36.08 | 41.08 | 46.08 | 55.1 | 65.1 | 75.1 | 85.12 | |

| Max | 17.23 | 19.275 | 19.275 | 22.275 | 24.275 | 27.275 | 32.33 | 36.33 | 41.33 | 46.33 | 55.4 | 65.4 | 75.4 | 85.47 | |

| t | Min | 11 | 12 | 13.5 | 15.5 | 18 | 19 | 24 | 28 | 34 | 38 | 43 | 48 | 54 | 60 |

| Hurefu hweshinda=b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

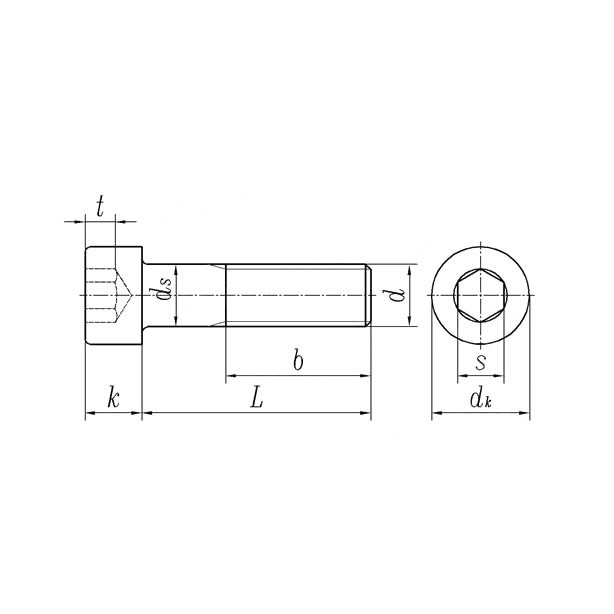

Detail drawing

Ndeupi musiyano uripo pakati peMhangura, Brass, Bronze?

Mhangura, Brass uye Bronze, neimwe nzira inozivikanwa se "Red Metals", inogona kutaridzika zvakafanana pakutanga. Asi ivo vane misiyano yakawanda muchinhu, kuita uye zvichingodaro.

Mhangura

Mhangura inoshandiswa mumhando dzakasiyana-siyana dzezvigadzirwa nekuda kwekunaka kwayo kwemagetsi uye kupisa kwemhepo, simba rakanaka, kuumbwa kwakanaka uye kushorwa kwekuora. Pombi uye pombi fittings anowanzo gadzirwa kubva masimbi aya nekuda kwekupokana kwawo. Dzinogona kutengeswa nyore nyore uye dzakashongedzwa, uye dzakawanda dzinogona kugadzirwa neakasiyana gasi, arc uye nzira dzekupikisa. Ivo vanogona kukwenenzverwa uye kubhurwa kunenge chero inodiwa magadzirirwo uye kupenya.

Kune mamakisi eCopper isina kurongeka, uye anogona kusiyana muhuwandu hwetsvina irimo. Oxygen-isina mhangura mamakisi anoshandiswa zvakananga mumabasa uko yakakwirira conductivity uye ductility inodiwa.

Chimwe chezvinhu zvakakosha zvemhangura ndiko kukwanisa kurwisa mabhakitiriya. Mushure mekuongororwa kwakawanda kweantimicrobial neEnvironmental Protection Agency, zvakaonekwa kuti 355 copper alloys, kusanganisira mabhurashi akawanda, akawanikwa achiuraya zvinopfuura 99.9% zvebhakitiriya mukati maawa maviri ekubatana. Kusvibiswa kwakajairwa kwakawanikwa kusakanganisa kushanda kweantimicrobial.

Mhangura Applications

Mhangura ndiyo imwe yesimbi dzakatanga kuwanikwa. VaGiriki nevaRoma vakaigadzira kuva maturusi kana zvishongo, uye kune kunyange nhoroondo dzezvakaitika kare dzinoratidza kushandiswa kwemhangura kuchenesa maronda uye kuchenesa mvura yekunwa. Nhasi inonyanya kuwanikwa mumidziyo yemagetsi senge wiring nekuda kwekugona kwayo kuita magetsi zvakanaka.

Brass

Brass inonyanya kuve alloy ine mhangura ine zinc yakawedzerwa. Mabhureshi anogona kuve neakasiyana siyana ezinc kana zvimwe zvinhu zvakawedzerwa. Iyi misanganiswa yakasiyana-siyana inobudisa zvakasiyana-siyana zvezvivakwa uye kusiyana kwemavara. Yakawedzera huwandu hwezinc inopa izvo zvinhu zvine simba rakagadziridzwa uye ductility. Brass inogona kubva muruvara kubva kutsvuku kusvika kune yero zvichienderana nehuwandu hwezinc yakawedzerwa kune alloy.

Kana iyo zinc yemukati yendarira ichibva pa32% kusvika 39%, ichave yakawedzera kupisa-kushanda kugona asi kutonhora-kushanda kuchave kushoma.

Kana iyo ndarira ine inopfuura 39% zinc (muenzaniso - Muntz Metal), ichava nesimba rakakwirira uye yakaderera ductility (pakamuri tembiricha).

Brass Applications

Brass inowanzoshandiswa pakushongedza chinangwa kunyanya nekuda kwekufanana kwayo negoridhe. Iri zvakare rinowanzoshandiswa kugadzira zviridzwa zvemimhanzi nekuda kwekunyanya kushanda kwayo uye kusimba.

Bronze

Bronze is a alloy iyo inosanganisira kunyanya yemhangura pamwe nekuwedzerwa kwezvimwe zvinhu. Kazhinji kacho chinongedzo chinowedzerwa chinowanzoita tin, asi arsenic, phosphorus, aruminiyamu, manganese, uye silicon inogonawo kushandiswa kugadzira zvinhu zvakasiyana muzvinyorwa. Zvose izvi zvinoshandiswa zvinogadzira alloy yakaoma zvikuru kupfuura mhangura chete.

Bronze inoratidzwa neyakasvibira-goridhe ruvara. Iwe unogona zvakare kuziva mutsauko pakati pendarira nendarira nekuti ndarira ichange iine zvindori zvisina simba pamusoro payo.

Bronze Applications

Bronze inoshandiswa mukuvaka zvivezwa, zviridzwa zvemimhanzi uye menduru, uye mumaindasitiri ekushandisa senge bushings uye mabearings, uko yakaderera simbi pane simbi friction inobatsira. Bronze zvakare ine nautical application nekuda kwekupokana kwayo nekuora.

Packing

Nezvedu

* Iyo inotevera dhizaini inoratidza akasiyana kutengeserana incoterms. Ndapota sarudza yaunoda.

HOT-SALE PRODUCT

Hunhu Kutanga, Kuchengetedzwa Kwakavimbiswa