HDG DIN933 Hex Musoro Bolt Hot Dipped Galvanized

HDG DIN933 Hex Musoro Bolt Hot Dipped Galvanized

Tsanangudzo

KUKURUMIDZAMhinduro

KUKURUMIDZAquote

KUKURUMIDZADelivery

AKAGADZIRIRA KUENDERERA KUNHU

10000+ SKU mudura

Isu tinozvipira kune RTS zvinhu:

70% zvinhu zvinotumirwa mukati memazuva mashanu

80% zvinhu zvinotumirwa mukati memazuva manomwe

90% zvinhu zvinotumirwamukati memazuva gumi

Mahodha akawanda, ndapota taura nevatengi

| d | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | (M14) | M16 | |||||||||||||||||

| P | Pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | ||||||||||||||||

| a | Max | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 3.75 | 4.5 | 5.25 | 6 | 6 | ||||||||||||||||

| c | Min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.2 | ||||||||||||||||

| Max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | |||||||||||||||||

| da | Max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | ||||||||||||||||

| dw | A Kirasi | Min | 2.4 | 3.2 | 4.1 | 4.6 | 5.1 | 5.9 | 6.9 | 8.9 | 9.6 | 11.6 | 15.6 | 17.4 | 20.5 | 22.5 | |||||||||||||||

| B Kirasi | Min | - | - | - | - | - | 5.7 | 6.7 | 8.7 | 9.4 | 11.4 | 15.4 | 17.2 | 20.1 | 22 | ||||||||||||||||

| e | A Kirasi | Min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | |||||||||||||||

| B Kirasi | Min | - | - | - | - | - | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 18.72 | 20.88 | 23.91 | 26.17 | ||||||||||||||||

| k | Nominal | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | 8.8 | 10 | ||||||||||||||||

| A Kirasi | Min | 0.98 | 1.28 | 1.58 | 1.88 | 2.28 | 2.68 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | ||||||||||||||||

| Max | 1.22 | 1.52 | 1.82 | 2.12 | 2.52 | 2.92 | 3.65 | 4.15 | 4.95 | 5.45 | 6.56 | 7.68 | 8.98 | 10.18 | |||||||||||||||||

| B Kirasi | Min | - | - | - | - | - | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | 8.51 | 9.71 | ||||||||||||||||

| Max | - | - | - | - | - | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | 9.09 | 10.29 | |||||||||||||||||

| k1 | Min | 0.7 | 0.9 | 1.1 | 1.3 | 1.6 | 1.9 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | 5.96 | 6.8 | ||||||||||||||||

| r | Min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | ||||||||||||||||

| s | Max=Nezita | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | ||||||||||||||||

| A Kirasi | Min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | ||||||||||||||||

| B Kirasi | Min | - | - | - | - | - | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 16.57 | 18.48 | 21.16 | 23.16 | ||||||||||||||||

| d | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | (M45) | M48 | (M52) | ||||||||||||||||||

| P | Pitch | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 | |||||||||||||||||

| a | Max | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | 13.5 | 15 | 15 | |||||||||||||||||

| c | Min | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |||||||||||||||||

| Max | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | ||||||||||||||||||

| da | Max | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | 48.6 | 52.6 | 56.6 | |||||||||||||||||

| dw | A Kirasi | Min | 25.3 | 28.2 | 30 | 33.6 | - | - | - | - | - | - | - | - | - | ||||||||||||||||

| B Kirasi | Min | 24.8 | 27.7 | 29.5 | 33.2 | 38 | 42.7 | 46.5 | 51.1 | 55.9 | 59.9 | 64.7 | 69.4 | 74.2 | |||||||||||||||||

| e | A Kirasi | Min | 30.14 | 33.53 | 35.72 | 39.98 | - | - | - | - | - | - | - | - | - | ||||||||||||||||

| B Kirasi | Min | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | |||||||||||||||||

| k | Nominal | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | 28 | 30 | 33 | |||||||||||||||||

| A Kirasi | Min | 11.28 | 12.28 | 13.78 | 14.78 | - | - | - | - | - | - | - | - | - | |||||||||||||||||

| Max | 11.72 | 12.72 | 14.22 | 15.22 | - | - | - | - | - | - | - | - | - | ||||||||||||||||||

| B Kirasi | Min | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 | |||||||||||||||||

| Max | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | ||||||||||||||||||

| k1 | Min | 7.8 | 8.5 | 9.6 | 10.3 | 11.7 | 12.8 | 14.4 | 15.5 | 17.2 | 17.9 | 19.3 | 20.9 | 22.8 | |||||||||||||||||

| r | Min | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | 1.2 | 1.6 | 1.6 | |||||||||||||||||

| s | Max=Nezita | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | |||||||||||||||||

| A Kirasi | Min | 26.67 | 29.67 | 31.61 | 35.38 | - | - | - | - | - | - | - | - | - | |||||||||||||||||

| B Kirasi | Min | 26.15 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | |||||||||||||||||

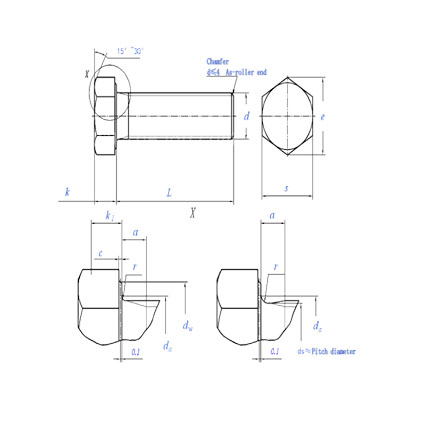

Detail drawing

HDG kazhinji inoreva kupisa-dip galvanizing.Kupisa-dip galvanizing kuita kuti simbi yakanyungudutswa iite pamwe nesimbi matrix kuti ibudise alloy layer, kuitira kuti matrix uye coating zvibatane.Kupisa-dip galvanizing ndiko kutanga kunyura simbi nesimbi, kuitira kubvisa iron oxide pamusoro pesimbi nesimbi, mushure mekutora, inocheneswa mutangi reammonium chloride kana zinc chloride aqueous solution kana aqueous solution. yakasanganiswa aqueous solution yeammonium chloride uye zinc chloride, yozotumirwa kune inopisa dip coating tank.Kupisa-dip galvanizing kune zvakanakira kupfeka yunifomu, kunamatira kwakasimba uye hupenyu hurefu hwebasa.

Kudzivirirwa kwekuora kunonyanya kutariswa nehupamhi hwemagalvanized layer, saka kuyerwa kwehukobvu kazhinji ndiyo nheyo huru yekutonga kunaka kwegirodhi.Iko kona uye nekukurumidza kwemhinduro kunewo simba guru.Naizvozvo, hazvigoneke kuwana yakazara yunifomu yekupfeka ukobvu.Nokudaro, kuyerwa kwehuwandu hwekunamatira haugoni kutongwa nechinhu chimwe chete (nzvimbo).Zvinongoreva kuyera avhareji yekunamatira huremu (g) pachikamu cheyuniti (㎡).Pane nzira dzakawanda kuyera adhesion uwandu, akadai chinoparadza chikamu metallographic observation nzira, pickling nzira, isingaparadzi firimu ukobvu mita nzira, electrochemical nzira, estimation nzira uremu musiyano pakati pezvinhu zvinouya uye zvinobuda, etc. Nzira dzinowanzoshandiswa ndeidzi. iyo firimu ukobvu gauge nzira uye pickling nzira.

Packing

Isu tinopa akasiyana siyana ekupakata kuti asangane neyakasiyana yekutumira nharaunda uye mutengo wekudzora.Mhando dzakanyanya kurongedzerwa matani mapaketi, mabhegi akarukwa, mabhokisi akawanda, mabhokisi mumabhokisi, pamwe nemapallet kana makesi emapuranga kuti asangane negungwa kana nendege zvinodiwa.Pazasi pane mafoto emhando dzakasiyana dzekurongedza dzatinopa kuti titarise.

Nezvedu

* Iyo inotevera dhizaini inoratidza akasiyana kutengeserana incoterms.Ndapota sarudza yaunoda.

HOT-SALE PRODUCT

Hunhu Kutanga, Kuchengetedzwa Kwakavimbiswa